Our production processes

Designing products, producing them, packaging and then dispatching them... this has been our area of expertise in the Aveyron region since 1989.

Designing products, producing them, packaging and then dispatching them... this has been our area of expertise in the Aveyron region since 1989.

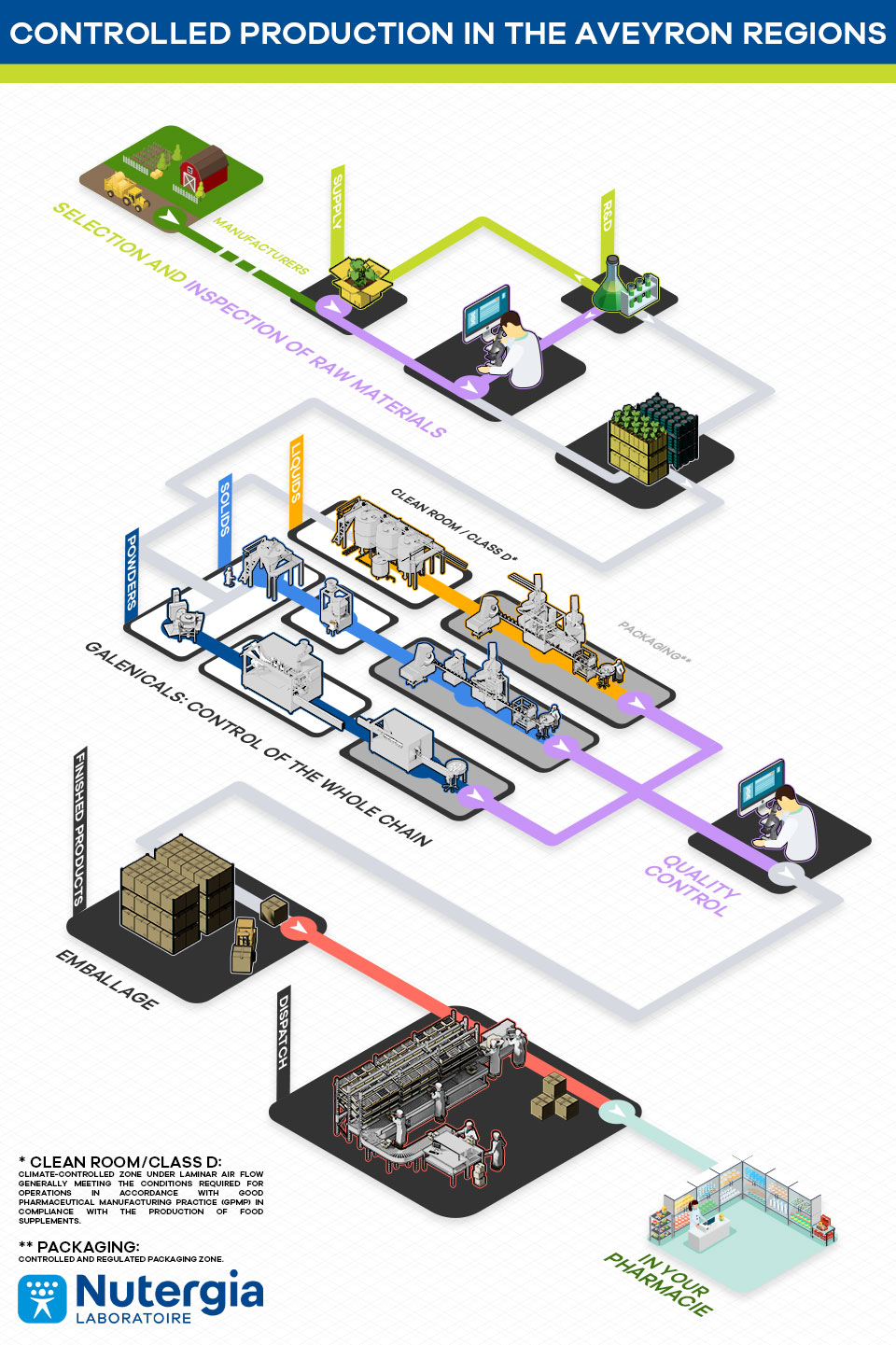

Find out about the main stages in our production processes in just 1 image.

* clean room/CLASS D: climate-controlled zone under laminar air flow generally meeting the conditions required for operations in accordance with Good Pharmaceutical Manufacturing Practice (GPMP) in compliance with the production of food supplements. ** packaging: controlled and regulated packaging zone.

As soon as they arrive, the raw materials are inspected by our quality control department (heavy metals, microbiology, pesticides, etc.).

The products are manufactured in class D clean rooms.

Laminar flow ensures there is no cross contamination.

Processing of raw materials varies according to (galenical) form of the final product: powders, solids or liquids.

There is an unbroken chain between manufacturing and packaging.

This step ends in quality controls.

The finished products are packaged and then sent to shipping who are responsible for delivering them to your pharmacy.